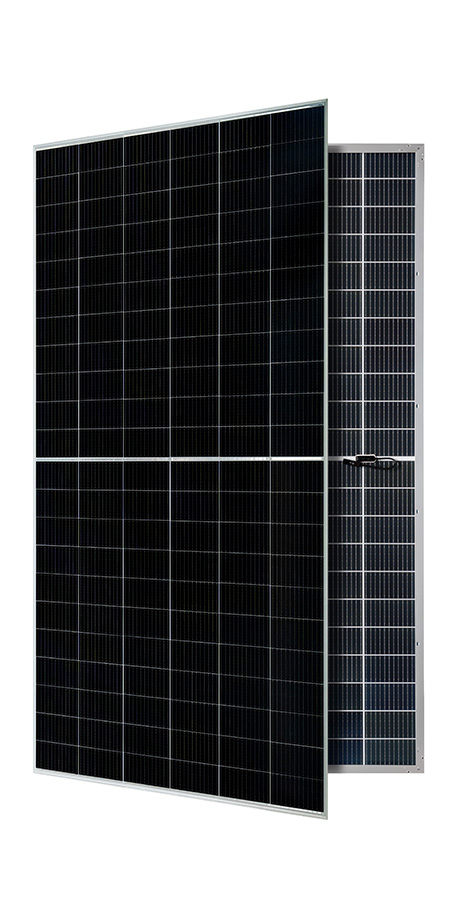

P series

Hardcore Energy, Reliable Technology

Features and Benefits

MBB Technology Reducing String & Busbar Loss

Even Cloudy or Foggy Days Better Weak Illumination Response

Better Temperature Coefficient More Power Generation

Multiple Weather Resistance Tests Wider Applicability

High Efficiency PERC Better Resistance Against PID

Zero LID Increase Power Generation

Higher Power Output Lower BOS Cost

Double-sided Generation Powerfully Energy Boost

Trustworthy Quality

100% Cells Sorting

Ensure Color and Power Difference. Ensure high yields, consistent performance and durability. First of 52 steps strict quality control and inspection process.

100% Inspection

Before and After Lamination. Most stringent acceptance criteria and tightest tolerance. Intelligent alarm and stop mechanism in case of any deviation or errors.

100% EL Testing

Before and Following Lamination. Ensure "Zero" micro crack monitoring before final inspection, Continuous line monitoring and video/photo record for each cell and panel.

100% Optional Testing

Ensure 3% Positive Power Tolerance. Comprehensive QC information management system with barcode ID. Quality traceable system in place to allow quality data flow constantly.

Production Information

|

P-type Modules |

||||

|

Module Type |

Power Range |

Maximum Efficiency |

Dimension |

|

|

182 P-type Monofacial / Bifacial Module |

405W - 415W |

21.25% |

1722x1134x35/30mm |

|

|

450W - 460W |

21.25% |

1909x1134x35/30mm |

||

|

495W - 505W |

21.27% |

2094x1134x35/30mm |

||

|

545W - 555W |

21.48% |

2278x1134x35/30mm |

||

|

210 P-type Monofacial Module |

535W - 545W |

21.34% |

1960x1303x35/30mm |

|

|

595W - 605W |

21.38% |

2172x1303x35/30mm |

||

|

655W - 665W |

21.41% |

2384x1303x35/33mm |

||

|

210 P-type Bifacial Module |

530W - 540W |

21.14% |

1960x1303x35/30mm |

|

|

590W - 600W |

21.20% |

2172x1303x35/30mm |

||

|

650W - 660W |

21.25% |

2384x1303x35/33mm |

||

See datasheet for details

FAQ

The biggest difference between P-type and N-type is the raw material silicon wafer and battery preparation technology. In terms of raw materials, according to the use of different doped elements of different silicon, can be divided into N-type cell and P-type cell. In the preparation technology, the P-type cell mainly adopts the traditional aluminum back-field battery (AI-BSF) and passivated emitter and back-side battery (PERC) technology, the preparation technology of n-type battery mainly includes tunneling oxide passivation contact cell (Topcon) , intrinsic thin film heterojunction cell (HJT) , all-back electrode contact cell (IBC) and all-diffusion cell (N-PERT).

P-type cell is the technology of emitter and back passivation, which uses the passivation film to passivate the back, instead of the traditional all-aluminum back field, enhances the reflection of light on the silicon substrate, and reduces the recombination rate on the back, the result is a 0.5% -1% improvement in cell efficiency.

The difference between 182 P-type and 210 P-type is the size of cell. The size of the 182p-type is 182x182mm, and the size of the 210p-type is 210x210mm.

The type of connection is the same but the technology of production is different.