Energy storage systems generate heat during operation due to internal electrical and chemical processes. If this heat is not effectively dissipated, it can raise the battery temperature, affecting performance, lifespan, and safety. High temperatures accelerate internal chemical reactions, leading to capacity loss, increased internal resistance, and potentially causing thermal runaway and fires. Thus, efficient thermal management is essential.

1. Components of Thermal Management

The primary role of a thermal management system for energy storage batteries is to maintain the batteries within a reasonable temperature range. This includes cooling when temperatures are too high, heating when too low, insulation during low-temperature shutdowns, and ensuring safety during thermal runaway incidents.

The thermal management system consists of:

Cooling System: Lowers temperature when batteries get too hot.

Heating System: Raises temperature when batteries are too cold.

Insulation System: Maintains temperature during low-temperature shutdowns.

Thermal Diffusion Protection System: Ensures safety during thermal runaway incidents.

2. Air Cooling Technology

Natural Cooling: Utilizes natural air pressure, temperature differences, and air density differences to dissipate heat. However, its efficiency is low, especially in confined spaces like containers or prefabricated boxes, making it hard to meet temperature control requirements.

Forced Air Cooling: Uses industrial air conditioners and fans to cool the batteries. Compressors and refrigerants work together to maintain the internal temperature lower than the external environment.

Advantages:

Simple structure

Easy installation

Low cost

Disadvantages:

Limited air heat exchange capacity, insufficient for large-capacity energy storage systems.

Low system efficiency.

Uneven cooling, leading to significant temperature differences between batteries.

3. Liquid Cooling Technology

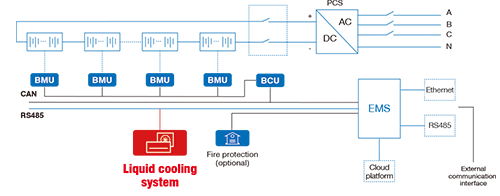

A liquid cooling system consists of battery cooling plates, water pipe circuits, and a cooling/supply system. Low-temperature coolant flows through the battery system, exchanging heat with the cells before returning to a heat exchanger to transfer heat to a low-temperature refrigerant, thus removing heat from the battery system.

Advantages:

High integration level, saving space and increasing energy density.

Stronger heat exchange capacity, ensuring better temperature consistency between batteries and higher charge/discharge rates.

Higher environmental adaptability, with battery modules meeting IP67 or higher standards.

Disadvantages:

Complex liquid cooling circuit design.

Potential environmental risks from heat exchange substances.

Safety risks from coolant leaks.

4. Development Trends

Integrated Thermal Management Systems: Combining multiple components and modules to reduce system costs and expand space, improving overall performance and efficiency while simplifying installation and maintenance.

Intelligent and Precise Control: Using advanced sensor technology, data analysis algorithms, and AI for precise temperature monitoring and prediction. Adjusting thermal management strategies based on real-time data and predictive models enhances safety and stability.

More Efficient Cooling Technologies: Liquid cooling, including new techniques like immersion cooling, is likely to see broader application due to its high efficiency in controlling battery temperature, reducing temperature differences, and extending battery life.