The photovoltaic (PV) industry has witnessed remarkable advancements, with several key technologies reshaping the landscape of solar energy. These innovations focus on improving efficiency, reducing costs, and enhancing the versatility of solar modules. Here’s a closer look at the trending technologies driving the industry forward:

One major breakthrough is diamond wire slicing technology, which significantly reduces the cost of slicing crystalline silicon. By using diamond-coated wires for high-speed cutting, this method outperforms traditional slurry slicing in terms of efficiency and cost-effectiveness. Monocrystalline silicon has already fully transitioned to diamond wire slicing, while multicrystalline silicon is rapidly following suit, signaling a paradigm shift in silicon wafer production.

PERC (Passivated Emitter and Rear Cell) technology has also become a staple of high-efficiency PV cells. Unlike conventional cells, PERC incorporates a passivated rear surface, reducing electron recombination and improving light reflection. This innovation significantly enhances cell efficiency. By the end of 2018, global PERC production capacity had reached 70GW, with further growth anticipated, solidifying its position as a leading technology in efficient solar products.

Another game-changing innovation is the integration of diamond wire and black silicon technology. Black silicon improves light absorption and cell efficiency by addressing the high surface reflectivity of traditional silicon. Although dry black silicon offers the highest efficiency gains, it requires costly equipment, limiting its widespread adoption to top-tier manufacturers. Wet black silicon provides a more cost-effective alternative, achieving efficiency increases of 0.3%-0.5% with lower capital investment.

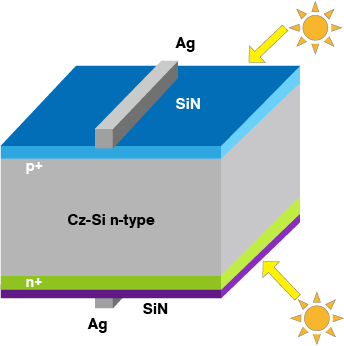

Bifacial solar cells represent another significant advancement, capable of capturing sunlight from both sides to boost energy generation. Enhanced with techniques like dual-sided printing and boron doping, these cells achieve rear-side energy gains of 10%-25%, depending on environmental conditions. N-type monocrystalline bifacial cells are increasingly expanding production capacity, further driving adoption in the market.

Multi-busbar (MBB) technology is another noteworthy innovation, featuring 12 busbars to improve current collection and reduce internal resistance. This design minimizes shading loss, enhances light absorption, and increases module power output by at least 5W. Additionally, MBB reduces the likelihood of microcracks and maintains stable energy output even in cases of cell damage.

Shingled module technology optimizes the layout of PV cells by slicing and overlapping them, creating a tightly packed configuration that increases cell density by over 13% compared to conventional modules. The absence of soldering ribbons reduces electrical losses, boosting module efficiency and power output. This technology represents a revolutionary step forward in high-efficiency module packaging.

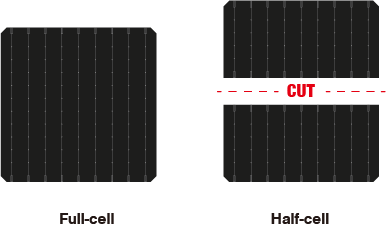

Lastly, half-cut cell technology involves splitting traditional cells into halves and rearranging them within the module. This reduces current mismatches, decreases internal power losses, and enhances overall output by approximately 10W compared to full-cell modules. Furthermore, it lowers hot spot temperatures by about 25°C, improving reliability and durability.

These cutting-edge technologies collectively underscore the PV industry's commitment to innovation. By continuously enhancing performance, lowering costs, and broadening applications, they are paving the way for a sustainable and efficient solar-powered future.