1. Overview of Half-Cell Technology

Half-cell technology involves splitting standard solar cells into two equal halves. Unlike conventional solar panels with 60 or 72 full-sized cells, half-cell panels typically feature 120 or 144 half-cells while maintaining the same overall design and dimensions as standard panels.

2. Half-Cell Cutting Process

The half-cell production process typically employs laser cutting, dividing a standard-sized solar cell into two equal halves along a direction perpendicular to the main busbars. These halves are then reconnected in series to form a complete circuit.

3. Electrical Characteristics of Half-Cells

Half-cell panels are encapsulated with tempered glass, EVA, and a backsheet, similar to conventional modules.

A typical solar panel contains 60 series-connected cells, each generating 0.5–0.6V, with a total operating voltage of 30–35V.

When half-cells are connected as in a standard module, they produce half the current and double the voltage, keeping the resistance constant.

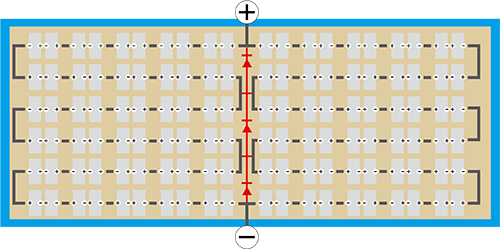

To match the voltage and current outputs of conventional panels, half-cell panels are designed with a series-parallel configuration, effectively combining two smaller sub-modules in parallel. This ensures that:

Each half-cell has the same open-circuit voltage as a full cell.

The current of each half-cell is halved, but the parallel design restores the total current to match full-cell modules.

The total circuit resistance is reduced to one-quarter of that of a full-cell module, significantly reducing energy losses.

4. Advantages of Half-Cell Technology

① Lower Packaging Losses

By reducing internal current and circuit resistance, internal energy losses are minimized. Power loss is proportional to current, so halving the current and reducing resistance to one-quarter lowers power loss by four times. This enhances the panel’s output and energy yield.

Lower internal losses also reduce the panel’s operating temperature. Under outdoor conditions, half-cell panels operate approximately 1.6°C cooler than conventional panels, improving conversion efficiency.

② Reduced Risk of Hot Spots from Shading

Half-cell panels handle shading better than standard modules

Unlike conventional panels with three cell strings, half-cell panels have six, functioning as six smaller modules.

Bypass diodes (marked in red in the diagram) isolate shaded areas from the rest of the panel, minimizing performance losses due to partial shading (e.g., from leaves or bird droppings).

Even if half the panel is shaded, the other half can continue to operate, ensuring higher overall efficiency.

③ Lower Current Reduces Hot Spot Temperature

Half-cell technology distributes current more effectively, improving performance, lifespan, and shading tolerance.

In cases of shading, affected cells can form hot spots due to excessive localized heating.

Half-cell panels, with twice the number of strings, experience only half the heat generation at hot spots. This minimizes damage, enhances durability, and extends the module’s lifespan.

④ Enhanced Shading Tolerance for Power Loss

In a solar array, multiple panels are connected in series within a string, and strings are connected in parallel.

In traditional panel designs, power loss in a single shaded panel affects the entire string.

In half-cell panels, bypass diodes create alternative pathways for current, allowing it to flow around shaded areas and reducing power loss. This improves performance and minimizes shading impact.

Half-cell solar panels represent a significant leap forward in solar technology, combining improved efficiency, durability, and shading resistance. Their advanced design ensures reliable performance even under challenging conditions, making them a preferred choice for modern photovoltaic systems.