Photovoltaic (PV) cells are typically made from semiconductor materials such as silicon and feature both positive and negative electrodes. When exposed to sunlight, the photovoltaic effect occurs, instantly converting light energy into electrical energy in the form of direct current (DC). This electricity can either be stored in batteries or converted to alternating current (AC) via an inverter to meet diverse energy needs. PV cells are often connected in series or parallel to form modules, which are then assembled into arrays for larger energy outputs.

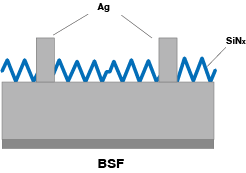

1. Aluminum Back Surface Field (BSF) Cells

Structure and Principle

BSF cells are a common type of solar cell that use an aluminum coating as the back electrode. This forms a rear electric field that helps drive electrons to the back electrode, enhancing energy conversion efficiency. The production process involves doping the silicon surface with phosphorus to create an N-type region, applying a film or coating to form a P-type region on the front, and forming a p-n junction. Finally, metal grids are added to collect current.

Development History

First proposed in 1973, BSF cells were the earliest commercialized crystalline silicon cell structure. By 2016, they accounted for over 90% of the market share.

Advantages

BSF cells are notable for their simplicity, cost-effectiveness, and mature technology.

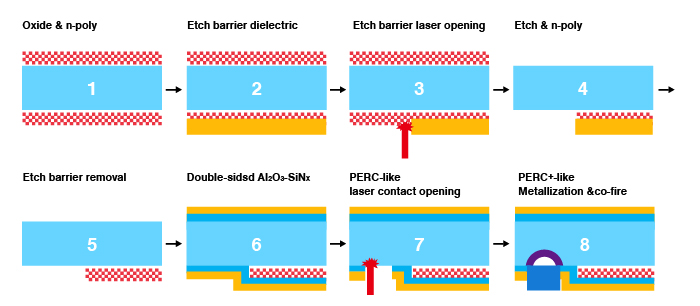

2. PERC Cells

Naming Origin

PERC stands for Passivated Emitter and Rear Cell.

Process and Performance

Building upon traditional BSF cells, PERC technology adds two key steps: rear surface passivation and laser opening, significantly boosting efficiency. The manufacturing process includes wafer cleaning and texturing, diffusion to create p-n junctions, laser doping for selective emitters, rear passivation, laser drilling, screen printing, sintering, and testing.

Advantages

PERC cells feature a simple structure, short manufacturing process, and high equipment maturity.

3. Heterojunction (HJT) Cells

Structure

HJT cells are hybrid solar cells combining crystalline silicon substrates and amorphous silicon films. They incorporate intrinsic amorphous silicon layers at the heterojunction interface to passivate the front and rear surfaces. The symmetrical structure includes an N-type crystalline silicon substrate, a P-i amorphous silicon layer on the light-facing side, an i-N amorphous silicon layer on the rear, and transparent electrodes and busbars on both sides. These are bifacial cells.

Advantages

HJT cells boast high efficiency, low degradation, a low temperature coefficient, high bifaciality, simplified processes, and suitability for thinner wafers.

4. TOPCon Cells

Technical Principle

TOPCon (Tunnel Oxide Passivated Contact) cells are based on the selective carrier principle. They feature an ultra-thin silicon oxide layer and a doped silicon layer on the rear, forming a passivated contact structure. This reduces surface and metal contact recombination, creating significant potential for efficiency improvement in N-PERT cells.

Process Features

TOPCon cells use N-type silicon substrates and require minimal changes to existing P-type production lines, such as adding boron diffusion and thin-film deposition equipment. They eliminate the need for rear openings and alignment, simplifying manufacturing and enhancing compatibility with PERC and N-PERT cell processes.

Advantages

TOPCon cells exhibit low degradation, high bifaciality, and a low temperature coefficient, yielding excellent performance in solar power plants.

5. IBC Cells

Structure and Principle

Interdigitated Back Contact (IBC) cells relocate all front-side electrode grid lines to the rear, arranging the p-n junctions and metal contacts in an interdigitated pattern. This reduces shading and increases light absorption. With no front-side metal contacts, IBC cells provide a larger active area for photon conversion.

Technology Integration

IBC cells can integrate with other technologies such as PERC, TOPCon, HJT, and perovskite, forming advanced hybrid cells like "TBC" (TOPCon-IBC) and "HBC" (HJT-IBC).

Application Potential

With their aesthetically pleasing design, IBC cells are well-suited for building-integrated photovoltaics (BIPV) and hold strong commercial prospects.

Conclusion

Each type of PV cell offers unique advantages and plays a pivotal role in advancing solar power technologies. Through continuous innovation, these technologies are driving the growth and transformation of the photovoltaic industry.