Ethan Brush, a technical expert from Acentech, recently released a report pointing out that as land becomes scarcer, more BESS are being deployed in densely populated residential areas, leading to increased noise issues.

As BESS become more common and are deployed in densely populated areas due to land scarcity, noise control measures are becoming increasingly important. In Europe and other densely populated regions, BESS noise issues are particularly severe, and the situation is also worsening in countries like the US and Australia. To address this challenge, BESS manufacturers need to focus more on acoustic design to meet the needs of residents.

Sources of Noise

Cooling Systems: Like other electronic devices, BESS operate best and safest at optimal temperatures and humidity levels. Various air or liquid cooling systems are used for this purpose, generating noise from vents, fans, and pumps, which is usually constant.

Power Conversion Systems (PCS): PCS convert the DC electricity from batteries to AC for use. During charging, inverters convert AC back to DC. This process generates heat, requiring cooling, typically with fans, which also produce noise. The switching process creates noise at frequencies like 120Hz or 100Hz and their harmonics, often heard as a hum. Transformers have three noise sources: core noise, coil noise, and fan noise. Some transformers use heat sinks instead of fans, which is quieter.

Mitigation Measures

Understanding Noise Standards: Worldwide, noise regulations aim to limit industrial noise in residential areas. These regulations vary in detail and clarity, with some specifying emission standards and others only setting decibel limits. BESS developers should consider environmental impact and resident concerns, even if not legally required.

Various standards from organizations like NEMA, IEC, IEEE, AHRI, ASHRAE, ANSI, and ISO provide guidelines for electrical and cooling systems. These standards help assess and manage BESS noise levels.

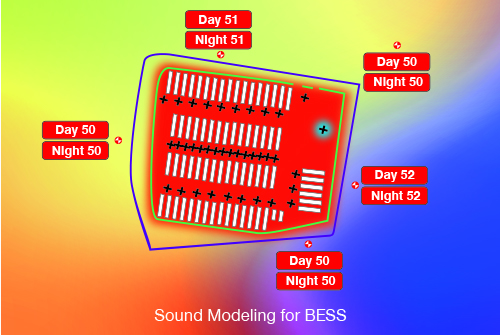

Sound Modeling for BESS: During the design phase, acoustic consultants and experts identify key noise sources from equipment. Suppliers may provide noise emission data, used to create acoustic models simulating the noise impact on surrounding environments. The model includes BESS equipment noise sources and terrain features, compared with noise standards.

Not all manufacturers provide noise data, complicating accurate noise modeling for BESS.

Measuring Environmental Sound Levels: Regulations, like those from the Massachusetts Department of Environmental Protection, may require industrial facilities to keep noise levels within specific environmental thresholds. These levels are measured before installation or with the facility fully shut down. Measurements taken over a week or more in quiet weather conditions give a comprehensive sound profile.

Some regions set a fixed noise limit for BESS without requiring on-site verification, but environmental noise measurement methods are recommended to align modeling results with existing conditions.

Noise Control

Noise control in BESS is a continuous improvement process. If design and layout exceed noise limits, acoustic consultants must design solutions to reduce noise. Effective noise control can be achieved by considering the source, path, and receiver of the noise.

Operators can integrate mitigation measures into the facility’s acoustic model, ensuring predicted noise levels meet standards. After installation, sound levels are measured to verify compliance, usually at night when ambient noise is lowest. This involves turning all BESS equipment on and off to assess overall noise characteristics.

Measurement equipment must meet international accuracy standards and be classified based on precision and performance.