Laser technology plays a crucial role in PV production, particularly in key stages of solar cell manufacturing. Whether it's crystalline silicon or thin-film cells, laser processing is widely used for cutting, shaping, passivation, and scribing, enhancing both production efficiency and product performance.

1. Edge Passivation of Solar Cells

High-energy lasers are used to passivate the edges of solar cells, reducing power loss. The grooves formed by the laser help to significantly lower energy loss caused by leakage currents, from the 10-15% typically seen with chemical etching to only 2-3% with laser technology.

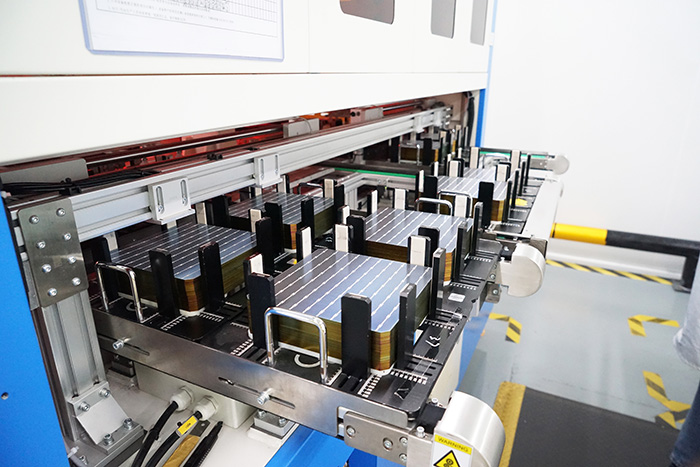

2. Scribing and Alignment

Laser scribing is commonly used in automatic stringing of solar cells. This method ensures tighter and more precise alignment of cells in a solar module, reducing storage costs and improving module efficiency.

3. Cutting and Dicing

Laser-based cutting and dicing of silicon wafers are among the most advanced techniques today, offering high precision, repeatability, operational stability, and fast processing speeds.

4. Silicon Wafer Marking

One prominent application of lasers in PV manufacturing is marking silicon wafers without affecting their conductivity. This helps manufacturers track the solar supply chain and ensure consistent quality.

5. Thin-Film Ablation

In thin-film solar cells, selective ablation of layers using lasers is essential for electrical isolation. Thin-film deposition must be rapid, without damaging the glass substrate or other layers. Incorrect laser ablation can lead to circuit damage and cell failure. To ensure stability and uniformity in energy generation, precise power adjustments of the laser beam are required during production.

6. Power and Beam Control

Manufacturers and researchers measure laser beam power to customize and fine-tune lasers for specific applications. High-power detectors and advanced monitoring tools are used to maintain 24/7 production with consistent beam quality. For thin-film PV, laser beam properties such as size, shape, and uniformity are more critical than raw power.

7. Beam Quality for Thin-Film Applications

When ablating electronic materials in thin-film PV, the shape, size, and strength of the laser beam significantly impact performance, especially in preventing leakage currents in the cells. Accurate beam control ensures proper circuit formation on the glass substrate without causing damage.

8. New Materials and Technologies

Perovskite, a new material in PV production, offers a cheaper and environmentally friendly alternative to traditional crystalline silicon cells. Its vapor deposition process also benefits from laser technology, showing that lasers have become an essential tool for solar cell manufacturing.

In summary, laser processing technology is a highly reliable and indispensable tool in modern solar cell production, enhancing both precision and efficiency across various stages of manufacturing.